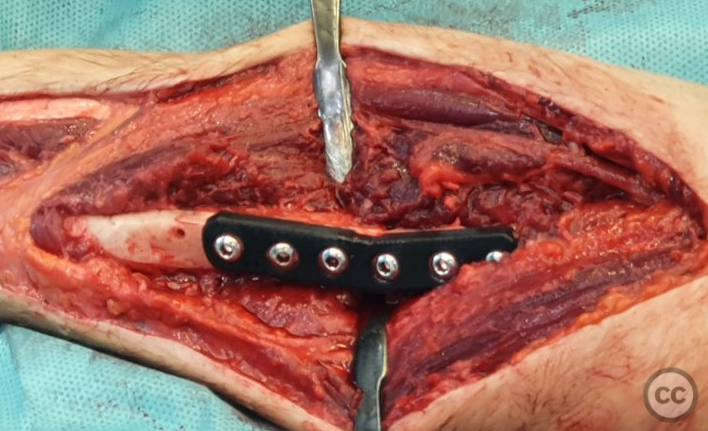

3D printed saw guides and provisional plate for corrective osteotomy of the radius

Score and Comment on this Case

Clinical Details

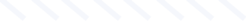

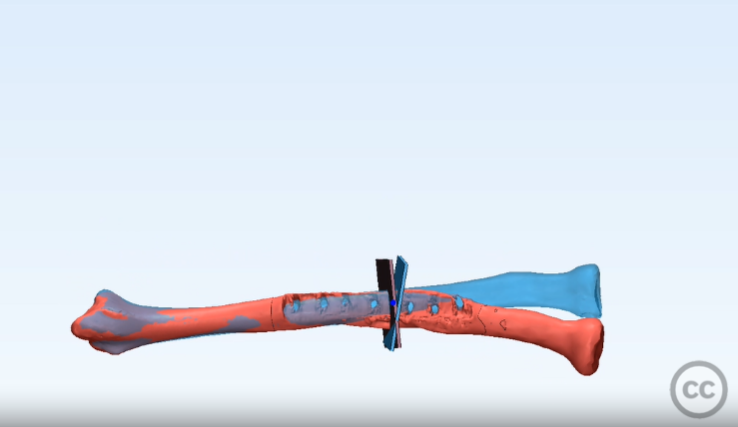

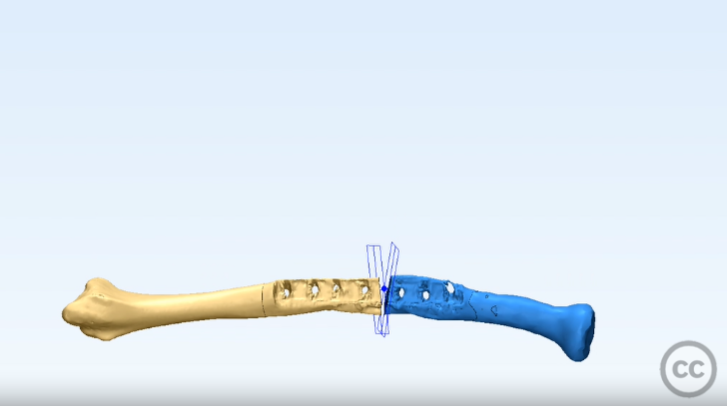

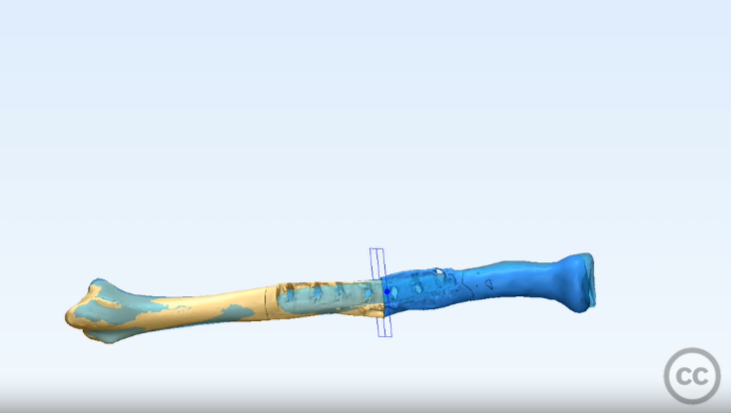

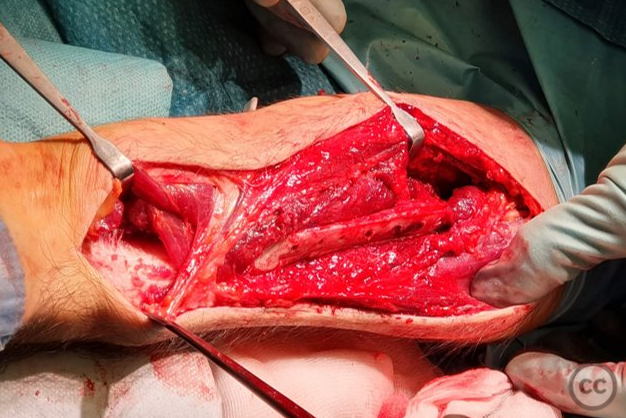

Clinical and radiological findings: History: 25 year old refugee. Radial shaft fracture as 15 year old in Middle East. Close reduction + casting. New injury during casting. Surgery with open reduction and plate fixation in another Middle-East country. Complains over pain and reduced rotation, cannot hold pen in normal fashion. Exam: lacks 40 degrees pronation, lacks some supination as well, tender with pronation. Radiograph: Radius mal-union

Preoperative Plan

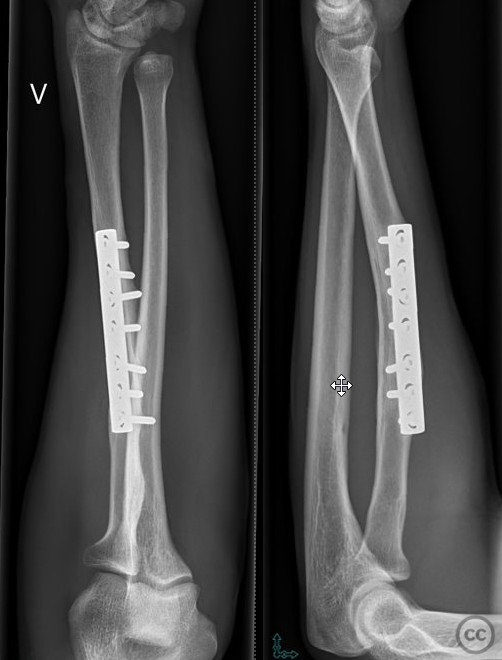

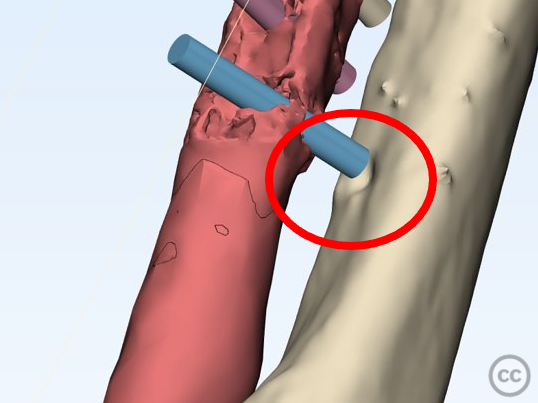

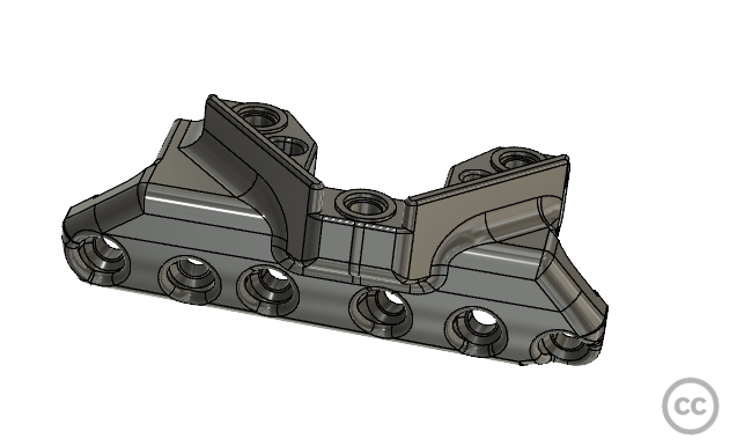

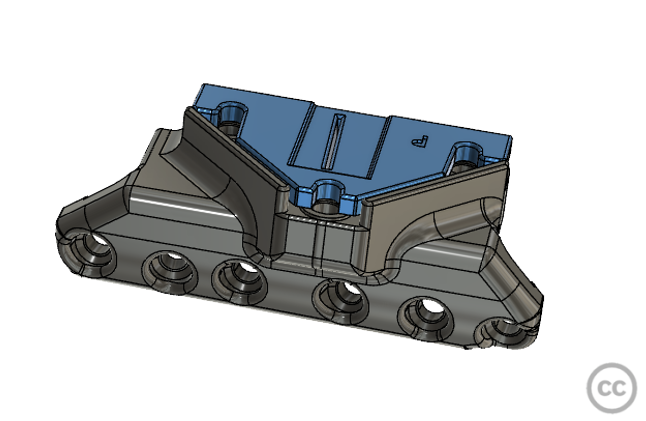

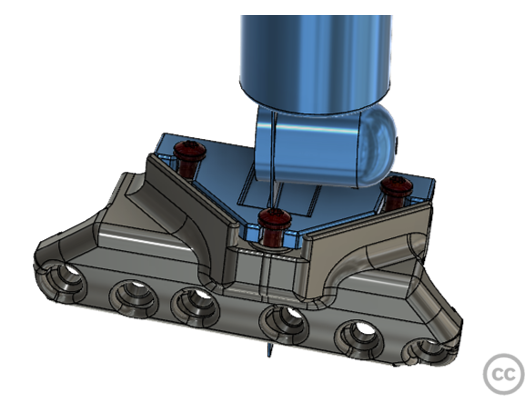

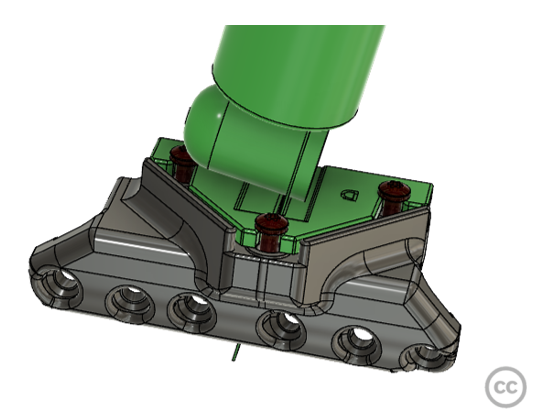

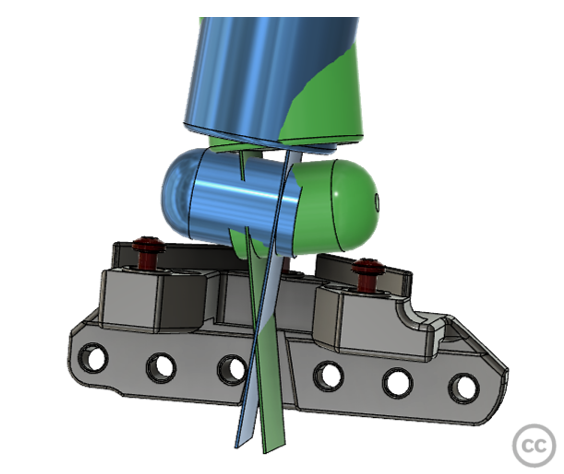

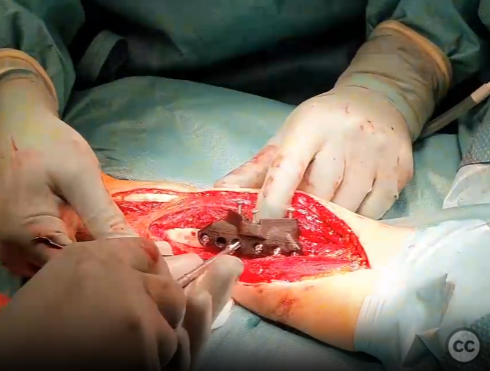

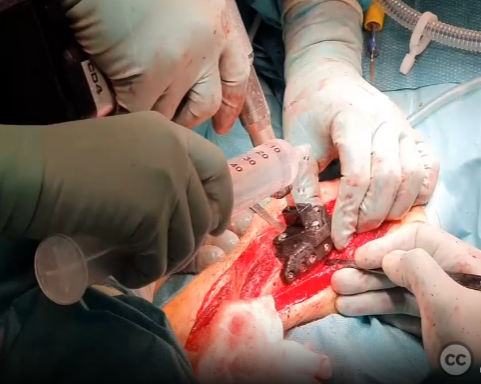

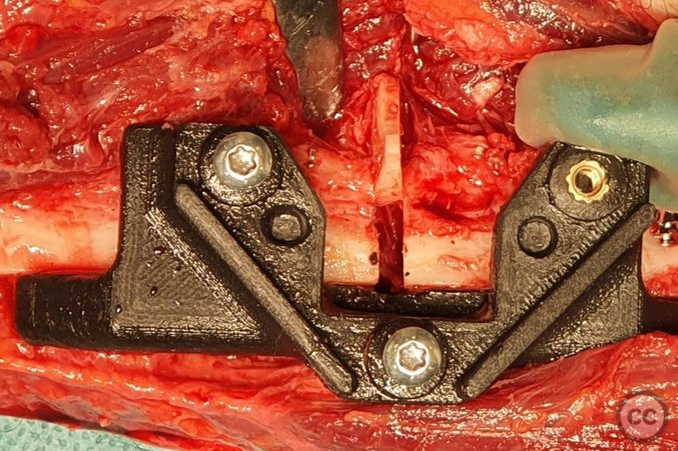

Planning remarks: 3D print of the injured arm demonstrated dynamic collision between radius + ulna with screw interference on pro/supination. Virtual surgical planning used a 3D CT-based-mesh of the non-injured side (blue), to define the level and degree of deformity, and plan a single multiplanar corrective osteotomy. CAD was used to create a modular osteotomy guide with 2 saw insert sleeves. A 3D printed temporary reduction plate (green) was then applied using the old screw holes to hold reduction pending definitive plating.

Surgical Discussion

Operative remarks:Credit to: Max Temmesfeld - Akershus Universitetssykehus

PubMed® Literature Review

Generated by The Literature - Realtime PubMed® AnalysisSatria et al. (2022) demonstrated the efficacy of arthroscopy-assisted osteotomy combined with 3D-printed guides for the reconstruction of intraarticular distal radius malunions, with improved QuickDASH and ROM postoperatively[1]. In a cadaver study by Caiti et al. (2021), a novel cast-based 3D-printed guide was evaluated for minimally invasive transfer of distal radius osteotomies, offering an alternative to patient-specific surgical guides or optical navigation systems[2].

Caiti et al. (2020) reviewed computer-assisted techniques for corrective distal radius osteotomy procedures, emphasizing the role of 3D-printed guides in restoring anatomical alignment and function[3]. Willemsen et al. (2021) compared synthetic CT and CT-based workflows for 3D-printed saw guides used in lower arm osteotomies, noting that synthetic CT could potentially avoid radiation exposure without compromising osteotomy results[4].

Belloti et al. (2021) employed 3D printing for planning corrective osteotomies of distal radius malunions, leading to improved palmar tilt, ulnar variance, and radial inclination radiographically[5]. Caiti et al. (2018) investigated the positioning accuracy of custom 3D-printed surgical guides for the radius, examining different fitting locations and guide designs, and suggesting further research to improve guide stability and positioning accuracy[6].

Temmesfeld et al. (2020) reported on an 18-year-old patient with intra-articular malunion of the distal radius who underwent a successful corrective osteotomy using in-house produced patient-specific surgical guides, highlighting the potential for low-cost 3D printing solutions[7]. Kim et al. (2017) proposed a graphic overlay method for selecting osteotomy sites in chronic radial head dislocation, using 3D computer images and software for simplifying the process, and validated the approach with 3D-printed bone models[8]. Inge et al. (2018) showcased a low-cost workflow for 3D printing in corrective osteotomy of malunited distal radius fractures, offering a cost-effective preoperative planning solution[9].

In summary, recent advancements in 3D printing technology have demonstrated significant potential for improving the accuracy and efficacy of osteotomy procedures in distal radius malunions. These innovations offer customizable, cost-effective solutions that can minimize radiation exposure while enhancing surgical outcomes.

References:

[1] https://pubmed.ncbi.nlm.nih.gov/35853284/

[2] https://pubmed.ncbi.nlm.nih.gov/33475897/

[3] https://pubmed.ncbi.nlm.nih.gov/31329563/

[4] https://pubmed.ncbi.nlm.nih.gov/33914209/

[5] https://pubmed.ncbi.nlm.nih.gov/34134854/

[6] https://pubmed.ncbi.nlm.nih.gov/29110185/

[7] https://pubmed.ncbi.nlm.nih.gov/31899717/

Search for Related Literature

Dr Ed Oates

- Germany , Schleswig Holstein

- Area of Specialty - General Trauma

- Position - Specialist Consultant

Industry Sponsership

contact us for advertising opportunities

Article viewed 1191 times

16 Apr 2023

Add to Bookmarks

Full Citation

Cite this article:

Oates, E.J. (2023). 3D printed saw guides and provisional plate for corrective osteotomy of the radius. Journal of Orthopaedic Surgery and Traumatology. Case Report 6758743 Published Online Apr 16 2023.